Field Visit: Sana’a University Plant Protection Students Examine Pesticide Active Ingredient Analysis Mechanisms

- Categories news

- Date December 12, 2025

fourth level Students at the Department of Plant Protection, Faculty of Agriculture, Food and Environment, Sana’a University, conducted a field visit to the General Directorate of Plant Protection (GDPP). The purpose of the visit was to observe the specialized equipment used for the quantitative analysis of Active Ingredients in pesticides.

The visit included an in-depth introduction to the Gas Chromatography (GC) and High-Performance Liquid Chromatography (HPLC) instruments and their operational mechanisms. Students witnessed a practical demonstration involving the testing of pesticide samples. A detailed explanation was provided on the procedures carried out at the Pesticide Analysis and Concentration Centre, covering:

• Quality control testing for commercial pesticides.

• The determination of the active ingredient percentage, following these specific steps:

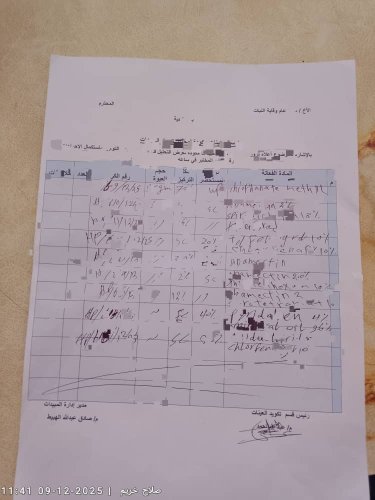

1. Receipt and Documentation: Pesticide samples are received, documented, and registered. This involves inspecting containers, checking labels, and verifying technical specifications.

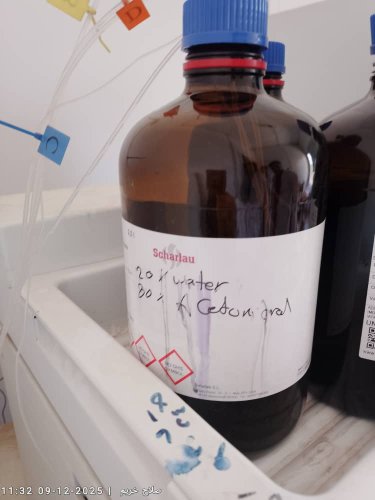

2. Standard Solution Preparation: Standard solutions of the pesticide are prepared at a specific concentration using high-precision instruments.

3. GC Analysis: Analysis is conducted using the GC instrument. A technician explained the method for detecting and quantifying the pesticide concentration.

4. Result Comparison: The analytical results are compared against approved specifications, whether they are international standards or reference data provided by the manufacturer.

In addition, several supplementary tests are conducted in the center to ensure product quality and stability:

• Thermal Stability Test: Pesticide samples are exposed to elevated temperatures (typically 54 C° for 14 days or 45C° for two months) to study the compound’s stability and resistance to decomposition or changes in chemical/physical properties.

• Long-term Stability Test: The pesticide is stored under normal conditions (room temperature of 25C° ± 2° and relative humidity 60%) for a period of up to two years. Periodic checks are performed to ensure the stability of the active ingredient and to confirm the absence of precipitation, color change, or viscosity alteration.

• In-use Stability Test (Post-Opening): It aims to examine the stability of the pesticide after the container has been opened and partially used. The aim is to understand the effect of exposure to air and humidity on the pesticide’s composition during its typical usage period.

• Physical and Chemical Properties Tests: Standard tests are conducted to measure properties such as pH, viscosity, density, and emulsification or water solubility characteristics, ensuring the pesticide’s quality and stability during storage and transport.

This specialized training aims to enhance the students’ knowledge of the procedures for receiving products for testing and to familiarize them with the operational mechanisms and methodologies of the sophisticated equipment used in active ingredient analysis and testing.

The training was conducted under the supervision of Dr. Safaa Hadwan, who provided scientific and field guidance, and Eng. Sadeq Al-Habeet, Director of Pesticides, whose valuable directions and expertise supported the training.

Sana’a University extends its sincere gratitude to the General Directorate of Plant Protection, particularly Eng. Sadeq Al-Habeet and Eng. Ahmed Al-Koul, who directed the cooperation and organized the reception of students in small groups (five individuals every two days) for those interested in the training. Special thanks also go to the field supervisors who welcomed the students and introduced them to the procedures for receiving pesticide formulations and the experiments conducted on them.

Previous post

🐔 Realistic Poultry Farm Design Enriches Animal Production Students' Experience

December 12, 2025

Next post

From Lecture Hall to Lab: Food Science and Nutrition Students Apply Food Safety Standards in Practice

December 13, 2025